Orbis’ advanced asset condition assessment and leak detection technologies can accurately assess pipe corrosion, life expectancy and pinpoint the location of leaks and bursts. The data they provide can support future investment decisions and help prioritise pipeline maintenance.

Pipeline diagnostics

- Investigator – pipeline condition assessment

- Crawler Inspection System

- Periscope 360

- Internal inspection without disruption

- Identifying areas of dangerous corrosion

- Accurate leak detection

- GPS tracking and plotting

- Location of services, defects and restrictions

- Valve assessment

LDS1000

LDS1000 is an advanced in-line inspection and leak detection system for long-distance, live potable water pipelines, up to 1,000m. The system is suitable for condition assessments, leak detection, mapping and locating.

- Live-feed CCTV and high-resolution digital camera images

- Real-time hydrophone for leak detection

- Sonde for underground pipeline location and GPS tracking

The LDS1000 has the ability to inspect up to 1,000m (3,280’) in a single insertion. It operates in pressures up to 10 bar (150 psi) and accommodates pipe diameters of 300mm (4-12”) and above. System meets requirements for British Standard BS 6920 – Suitability of non-metallic products for use in contact with water intended for human consumption with regard to their effect on the quality of the water.

Investigator

Investigator is an advanced in-line inspection and leak detection system for live pipeline inspection up to 100m. The system is suitable for condition assessment, leak detection, mapping and locating.

- Live-feed CCTV and high-resolution digital camera images

- Real-time hydrophone for leak detection

- Sonde for underground pipeline location and GPS tracking

The system can access pipelines through live fire hydrants and inspect lengths up to 100m (330’). Investigator operates in pressures up to 10 bar (150 psi) and accommodates pipe diameters of 100-300mm (4-12”). System meets BS 6920 requirements for non-metallic products in contact with water.

Crawler Inspection System

The Crawler Inspection System is able to perform detailed visual inspections of pipelines, using its 360-degree pan-and-rotate, forward and rear facing camera heads. It is suitable for non-pressurised pipes that are over 150mm wide and is capable of travelling up to 200m. With a steerable six-wheel drive, the system is robust, lightweight, durable and able to operate in harsh working conditions. The Crawler Inspection System has an extendable arm which allows the camera to be raised 120mm above its usual position. It provides high-resolution colour JPEG images and MPEG videos.

- Suitable for pipes over 150mm diameter

- Can travel up to 200m

- Camera 360-degree pan-and-rotate

- Provides colour JPEG images and MPEG videos

- Extension arm lifts camera 120mm

- New water mains inspection

- Pipe-wall lining condition analysis

- Evaluating joint conditions

- Water main tracing

- Water ingress

Periscope 360

The Periscope 360 is a waterproof, portable camera that can be used to inspect sewers and water pipelines. It is suitable for jobs where you only need visual pipeline data from the access point of the pipe. The camera can be used on any asset where full pipe bore hole access is viable.

- 360-degree view of the pipe from the access point

- Access pipe bore holes of 36mm and above

- Identify internal pipelining material

- Provides accurate visuals of sediment levels

- Creates visuals of flow

CASE STUDY

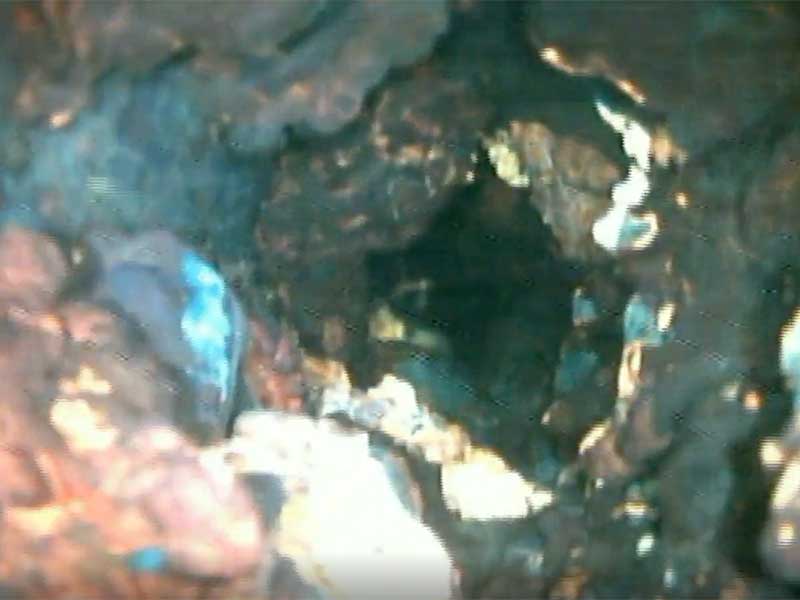

Tuberculated cast iron pipe

Orbis was contacted by a UK water utility because they were experiencing low pressure in the network. The low water pressure was resulting in the nearby pumping station having to work extra hard. Looking at this video you can see why. The 127mm (5”) pipe has been reduced to 25mm (1”) due to major tuberculation and build-up of corrosion products in one length of the pipeline. This demonstrates how effective the Orbis Investigator camera system is at quickly finding and accurately identifying blockages in pipes.

CASE STUDY

Finding pipeline leaks quickly

With the pipe only running at 1 bar pressure, there was definitely a leak, but it was proving to be tricky to find. The client had tried using their listening stick above ground, but with a compressor operating nearby and the additional sound coming from low pressure in the network, they could not hear a thing. Watch how the Orbis Investigator camera, moves backwards and forwards to identify the spot where the sound has the highest pitch. Once identified, it was located using the inbuilt sonde and sprayed up ready for excavation by the client. This proves why our camera system is highly effective in supporting our clients’ complex challenges on pipe networks.

CASE STUDY

Preventing future leaks

Using our LDS1000 camera system, we have worked in close partnership with one UK utility surveying over 5,000m of 355mm PE pipework. In this instance, the pipe was laid six years ago and there had been numerous bursts and issues, which resulted in the client needing a pipe survey to identify whether there were any more leaks. We identified all the potential problem areas, providing back-up data and clear images. The first image shows an electrofusion joint, which was requested by the client; the second image demonstrates material changes in the pipe itself. The client was delighted with the results.

CASE STUDY

Quickly finding leaks

Network operatives at this UK water company had been trying to find the leak on this 152mm (6”) cast iron main without any luck. They had dug four dry holes with no luck. Working closely with the client and using the Orbis Investigator, we found and pinpointed the leak within an hour.

Would you like to purchase or hire our specialist equipment?

01.

Orbis has a team of operators who can survey your pipeline and report back

02.

You can hire equipment from us with the option of training

03.

Or purchase the equipment with the option of a maintenance service

01.

Orbis has a team of operators who can survey your pipeline and report back

02.

You can hire equipment from us with the option of training

03.

Or purchase the equipment with the option of a maintenance service

Interested in learning more about our diagnostic equipment?

Contact us today to discuss how we could help you manage your network.